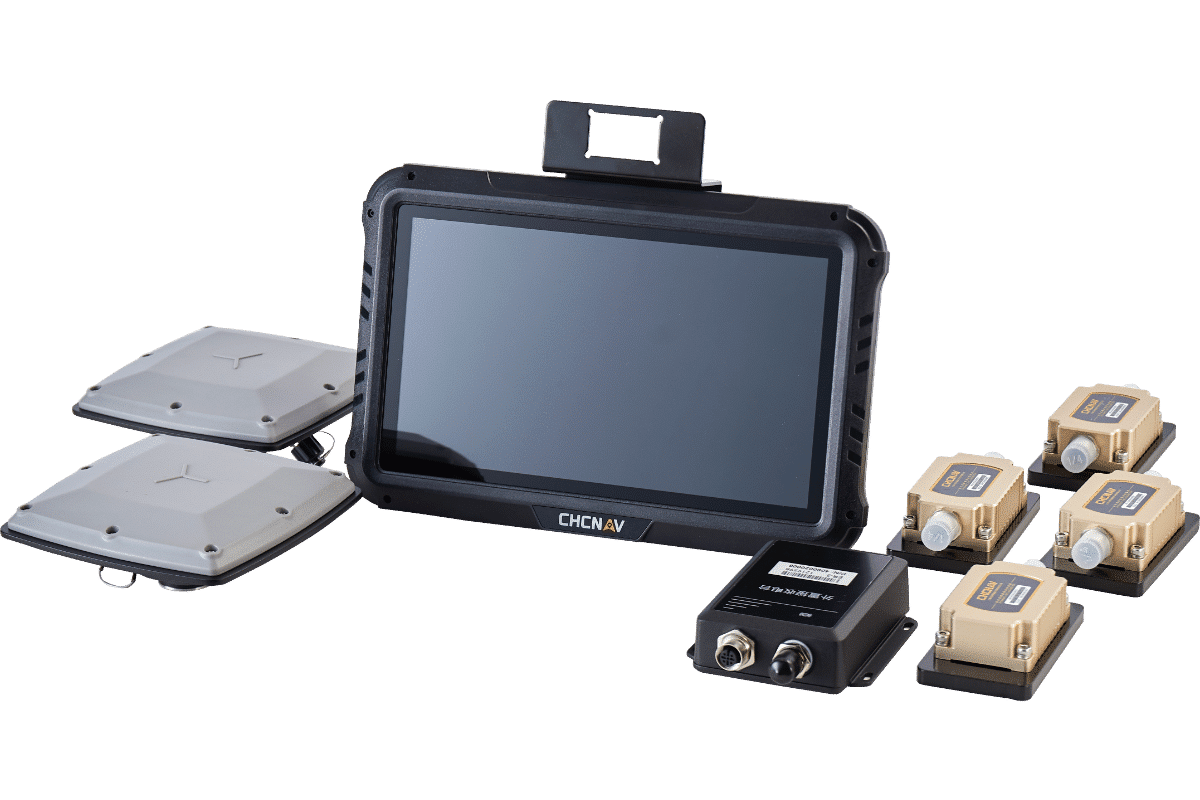

Machine Control Products

What is CHCNAV machine control?

What it Does

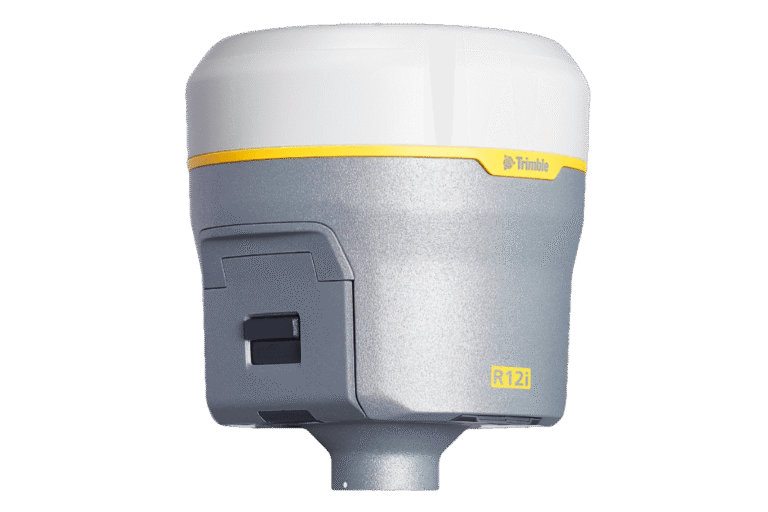

Machine control software plays a crucial role in enhancing the accuracy, efficiency, and productivity of construction and excavation projects. This software integrates with advanced hardware like GNSS systems and sensors to provide your operators with real-time guidance, enabling precise control over heavy machinery.

By processing design data and guiding machinery in real time, machine control software ensures that tasks such as excavation, grading, and trenching are carried out with minimal errors and maximum efficiency. Ideal for use in construction, earthworks, and roadworks, this software will improve operational precision and reduce project timelines.

Functionality

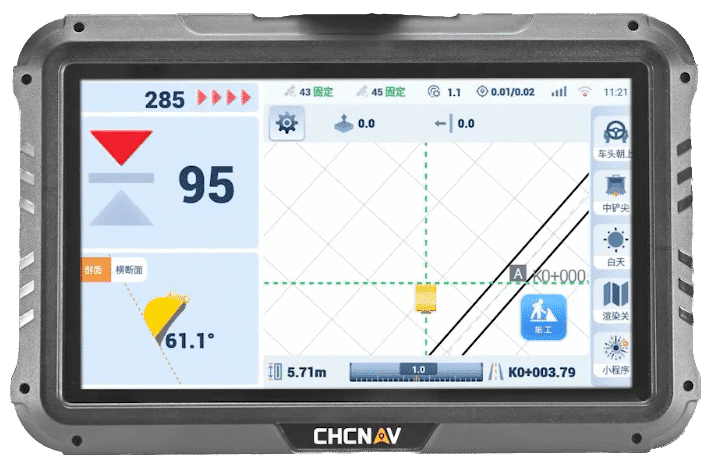

Machine control software takes data from design models and geospatial technologies, such as GNSS sensors, and uses it to provide real-time, actionable insights for equipment operators. With this software, operators can receive precise positioning data, allowing them to adjust equipment movements to stay on target with plans. The equipment supports a range of functions, from real-time depth measurements and slope management to full 3D excavation and grading. These capabilities make machine control software invaluable for tasks requiring high accuracy, such as mass excavation, utility trenching, and road construction.

The software simplifies the complex task of controlling machinery, automating key processes, and enabling operators to maintain continuous progress on-site with real-time feedback. With features like real-time guidance, slope and depth control, and error reduction, the software helps to increase productivity while ensuring compliance with design specifications.

Functionality

Machine control software takes data from design models and geospatial technologies, such as GNSS sensors, and uses it to provide real-time, actionable insights for equipment operators. With this software, operators can receive precise positioning data, allowing them to adjust equipment movements to stay on target with plans. The equipment supports a range of functions, from real-time depth measurements and slope management to full 3D excavation and grading. These capabilities make machine control software invaluable for tasks requiring high accuracy, such as mass excavation, utility trenching, and road construction.

The software simplifies the complex task of controlling machinery, automating key processes, and enabling operators to maintain continuous progress on-site with real-time feedback. With features like real-time guidance, slope and depth control, and error reduction, the software helps to increase productivity while ensuring compliance with design specifications.

Using Tri-Site

Tri-Site’s machine control software simplifies construction and excavation tasks, providing real-time guidance to improve accuracy and efficiency. With ongoing support, we will ensure you get the most out of your system, reducing errors and keeping you aligned with design plans. With a wealth of experience in surveying, we can offer assistance from installation to maintenance, and ensure seamless integration with existing equipment. We will help you get the most out of your machine control system.

Tri-Site’s machine control software simplifies construction and excavation tasks, providing real-time guidance to improve accuracy and efficiency. With ongoing support, we will ensure you get the most out of your system, reducing errors and keeping you aligned with design plans. With a wealth of experience in surveying, we can offer assistance from installation to maintenance, and ensure seamless integration with existing equipment. We will help you get the most out of your machine control system.

Features

Offers precise positioning of machinery, aligning equipment with design plans to ensure accuracy and reduce rework.

Enables operators to load and visualiae 3D design models directly within the software for real-time, on-the-job guidance

Automatically adjusts the machine's operation to maintain the correct slope and depth, ensuring tasks such as grading and excavation are carried out to specification.

Integrates with GNSS systems, sensors, and other construction equipment, ensuring a smooth workflow across the entire project.

Reduces human error by providing automated guidance and detailed feedback on machine operations, allowing for greater consistency and fewer mistakes.